The Buzz on Aws Cwi

The Buzz on Aws Cwi

Blog Article

Some Ideas on Aws Cwi You Should Know

Table of ContentsSome Ideas on Aws Cwi You Need To KnowThe Single Strategy To Use For Aws CwiThe Best Strategy To Use For Aws CwiThe 7-Minute Rule for Aws Cwi4 Simple Techniques For Aws Cwi

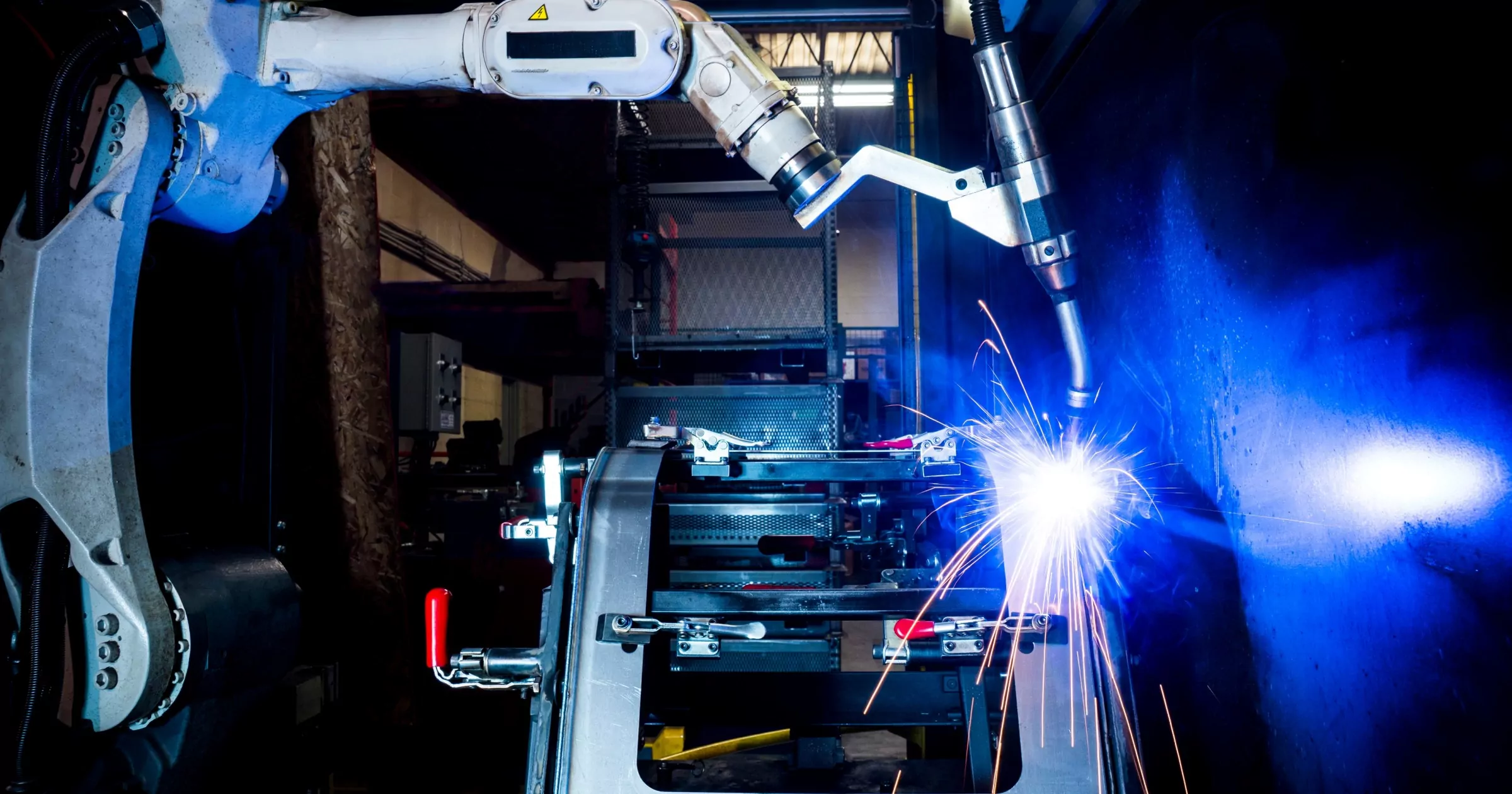

It ought to be noted that lots of tasks do not have demands for making use of qualified examiners and numerous business utilize their "finest" welders for this duty. While this may operate in some circumstances, it is absolutely harmful and it has lots of imperfections, some obvious and some not so noticeable. PFS developed a program where all Welding Inspectors are certified according to ASNT SNT TC-1A and AWS QC1 Certified Welding Assessor.

The duty of All PFS welding assessors start before the welding tools is also changed on. PFS Welding Examiners are trained to check the adhering to prior to welding begins: Welder is qualified. Base material is suitably tidy prior to welding.

The Greatest Guide To Aws Cwi

The WPS variables are being complied with by the welder. PFS Welding Inspectors after that audit all welding procedures throughout the manufacturing process to guarantee that all needs are being met. The advantages of utilizing Qualified Welding Examiners: ASNT and AWS Welding assessor certification has actually been widely approved by the United States and also a number of the major commercial countries on the planet.

Quality welding and extremely trained licensed welding examinations directly influences not only the performance of the product however the safety and security, life expectancy and dependability of the process that the welded part belongs to. One element of this, the Licensed Welder, is not adequate to guarantee success as with any kind of procedure, an independent collection of eyes that are trained to create an appropriate training process along with an effective and efficient documented tracking system as provided by a Licensed Welding Assessor, finishes the top notch control that guarantees that the customer is supplied the ideal possible high quality developed and documented product.

Do not be amazed that the majority of prominent sectors will certainly need you to use certified welding examiners to look after welding - https://sitereport.netcraft.com/?url=https://awscwi.com. This is done to minimize threat in what is typically seen as a rather high-risk market. An internal certified welding inspector will certainly have the ability to guarantee that your project is tailored to all the requirements of appropriate welding codes, assuring its quality

6 Simple Techniques For Aws Cwi

They'll likewise begin the procedure by conducting screening activities like welder efficiency qualification screening and welder procedure certification testing. This typically needs some weeks to finish and require to be reviewed and authorized before the onset of customers welding tasks. This makes sure the expertise of those dealing with your project.

Certified internal welding inspectors provide that careful eye. They will aid you by getting rid of irregularity during the welding processes (http://peterjackson.mee.nu/where_i_work#c2362). This in turn will benefit you with a quicker outcome and decreased production expenses at the end of stated process, permitting you to do even more with the sources that you currently have

These include ductility, joint geometry, cord feed speed, click here to find out more arc existing, arc voltage, base steel chemistry, protecting gas kind, filler steel chemistry, and tensile stamina to name a few. It is very important that you think about the value of having a licensed welding examiner before you start any task. Nevertheless, there is a real value in having a skilled review your task before you also strike the initial arc.

What Does Aws Cwi Mean?

A qualified welding examiner will certainly have had lots of years of experience which your organization will certainly have the ability to draw from. They will certainly have seen various challenges and successes and the lessons they have gained from them will aid your business to remain away from expensive reworks. This is why it is essential to find a welding company with a seasoned and extremely educated in-house licensed welding examiner on team.

Something went incorrect. Wait a moment and attempt again Attempt once more.

Since 1919, American Welding Society requirements, services, and programs have actually supported the men and ladies of welding in the United States. Today AWS is proud to claim that our impact extends the world, and we sustain countless welding specialists worldwide. To assist our worldwide participants, AWS contracts with organizations in countries throughout the globe to facilitate certification examinations.

To assist welders get professional welding accreditation, we offer company and individualized welding training programs for various expertise levels and market requirements and procedures (Weld Inspector). This technique of experience-based learning assists welders in training comprehend technological market standards and terminology while obtaining crucial hands-on abilities. Offering this kind of training indicates trainees need exceptional help from qualified specialists.

Not known Facts About Aws Cwi

Our weld assessment treatments help to validate the quality and preciseness of welds, while testing techniques help to recognize incongruities and ineffectiveness. These processes combined impact enhanced task performance along welders. OXARC's diverse series of welding refines our professionals can check is thorough with processes like: Shielded steel arc welding (SMAW) Gas tungsten arc welding (GTAW) Change core arc welding (FCAW) Gas metal arc welding (GMAW) We can also execute certification and qualification tests on plate, pipe, stainless steel and various other particularly asked for products.

Professional management, high quality product or services and dedication to our market maintain OXARC giving our clients with the products and remedies they require. Our personnel has a direct line of communication with the professionals in welding such as Lincoln Electric, ESAB, Avesta Stainless, Stoody, Select Arc, Eutectic and Thermal Arc, making our services a suitable choice for diverse markets.

Report this page